Magnetic Plates

Description

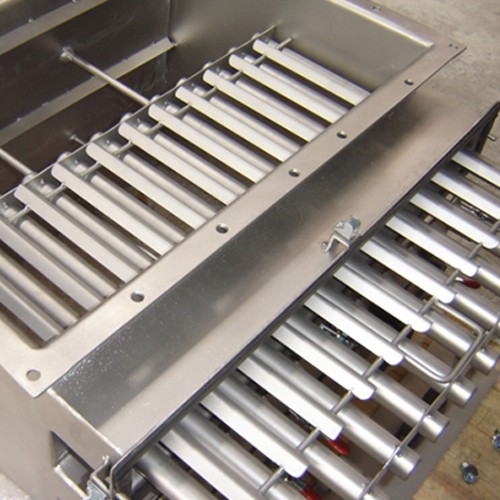

Magnetic plates are used to separate ferrous contamination from the raw material during the production process, whether they are dust, granules, nails, screws, chips, scraps and any other type of piece of iron that can contaminate the batch of material raw material or a finished product. In addition to performing this separation, the Magnetic Plate also prevents loose parts such as nails, screws, pieces of iron in general, from entering machinery and equipment damaging and causing greater damage.

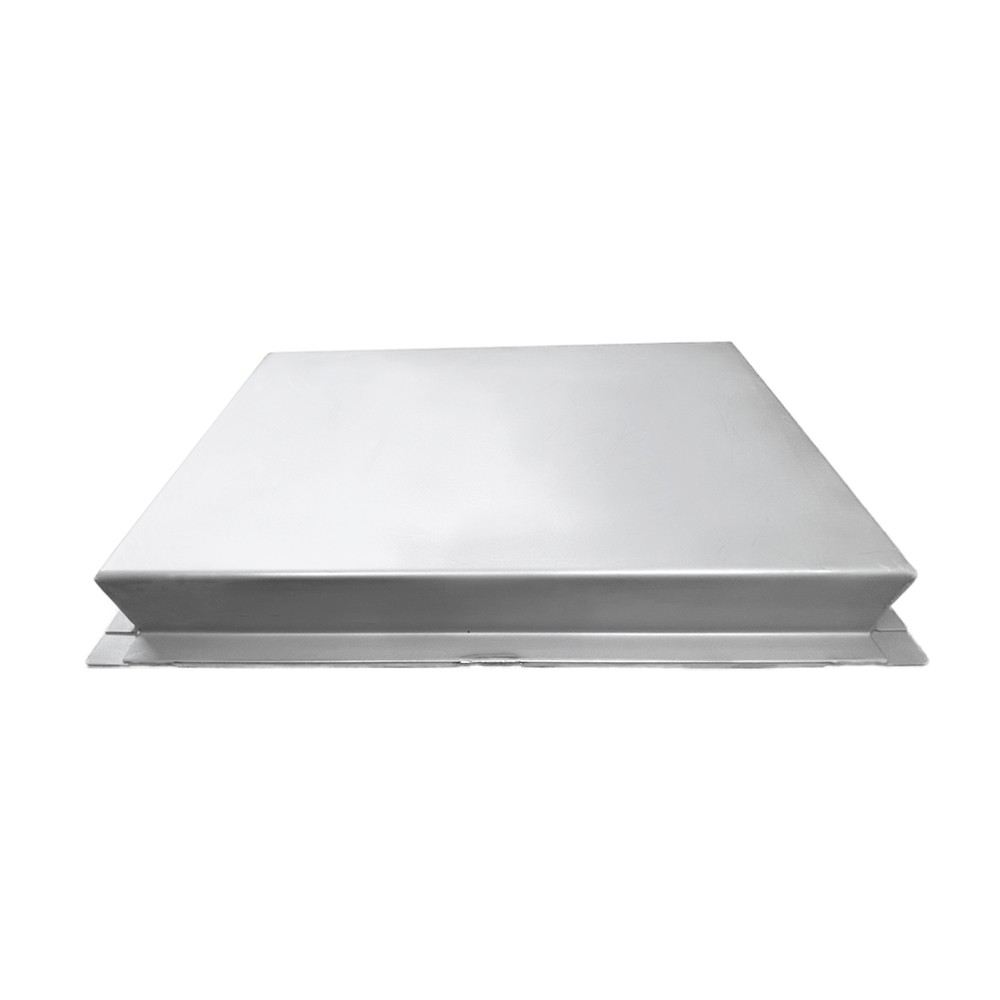

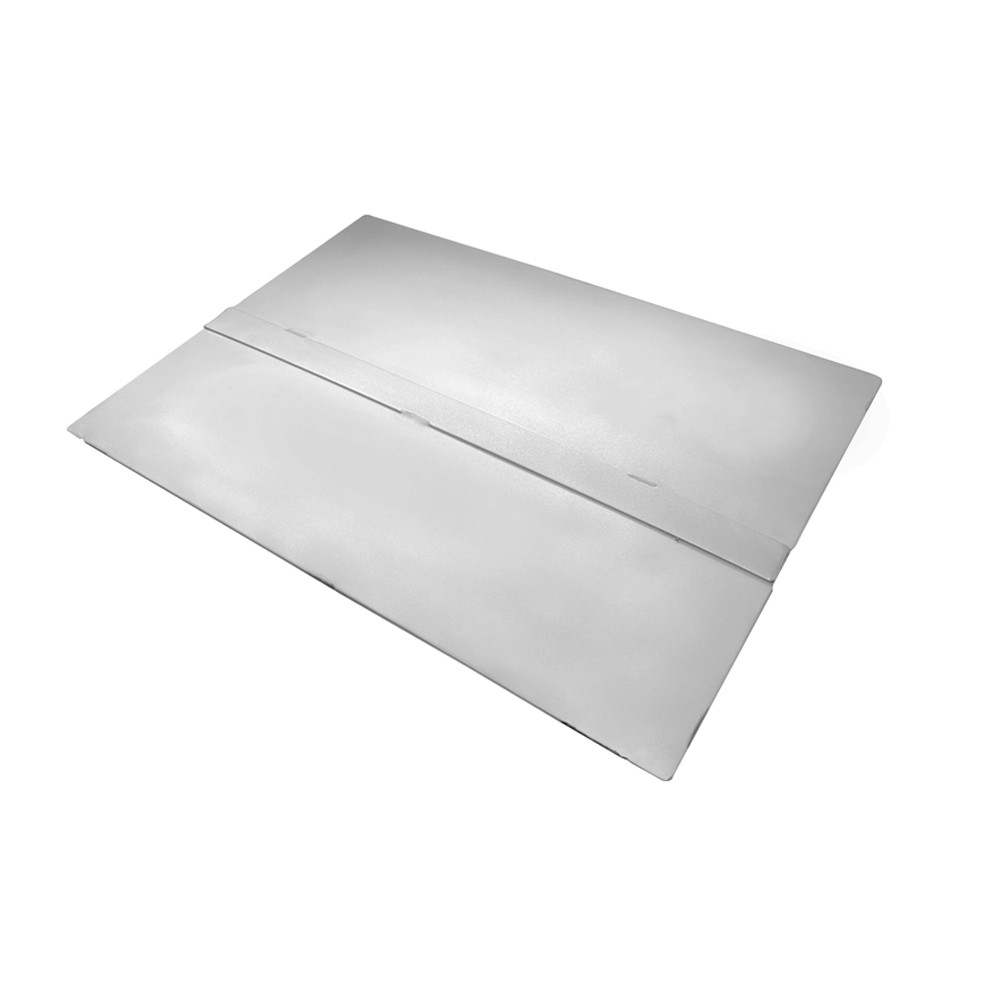

They are built in a robust AISI 304 stainless steel housing, in an exclusive system that prevents accidental disassembly, even if subjected to high vibrations. Its magnetic circuit is formed by permanent magnets of anisotropic strontium ferrite (oriented), of high energy, or optionally, alnico - for high temperatures, and neodymium of very high energy.

They are usually produced in four width models: 100, 150, 200 and 270 mm, the greater the width, the greater the attraction power of the plate. In addition to these models, they can be manufactured in other dimensions according to the customer's needs.

They are presented in three versions of faces: normal face, stainless steel face and suspended type. The normal face has a magnetic face with apparent poles in carbon steel, which concentrate the magnetic flux at the moment that some ferrous impurity is captured. The stainless steel face has the magnetic face entirely in AISI 304 stainless steel, which are ideal for installation where the presence of carbon steel is not allowed, such as food, corrosive products and others. The suspended type is designed to work suspended on the product and has a long-range magnetic circuit. In this case, it is convenient that the portion of the gutter that will be under the plate be made of non-ferromagnetic material.

Download:

DownloadUse

ATTENTION! CARE WITH MAGNETIC EQUIPMENT: We inform that people with any metallic prosthesis and/or pacemaker must keep their distance from magnetic equipment. Take due care when handling tools and/or metal parts near magnetic equipment, preventing possible accidents.