Magnetic Grid

Description

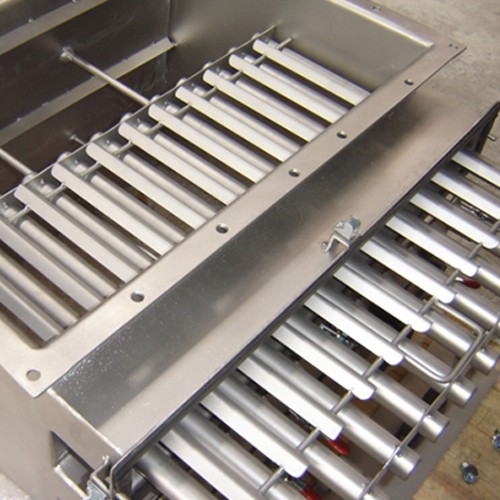

The magnetic grid is a type of equipment developed with the objective of separating ferrous contamination from the raw material during the production process. Mainly used in the industrial sector, from the plastics and derivatives industry, textiles, mining, chemicals, pharmaceuticals and food.

They have magnetic circuits specially developed to obtain a uniform attraction field at all points of the grid. The grids are manufactured in stainless steel AISI 304, with tubes of 1 "diameter, industrial finish (sandblasted) or sanitary (polished) and permanent magnetism. Neodymium magnets or ferrite magnets can be used for their production according to the needs of the customer and their application grids produced with neodymium magnets can obtain different surface magnetic fields, such as: 4,500 | 6,000 | 7,500 | 9,000 and 11,000 gauss - which operate at a temperature of up to 80ºC or, if necessary, up to 150ºC. grids produced with ferrite magnets have 2,000 gauss and operate at a temperature of up to 200ºC.

The grids can also be supplied in drawers and housings, for adaptation to pipes, ducts and silo outlets. With dispositions of rows of tubes, offset rows, row with upper deflectors and among other variations. It is advisable to consult our team of specialists to assist you in the correct sizing of your equipment and application.

In addition to avoiding contamination in raw materials with ferrous materials, be they dust, granules, nails, screws, chips, scraps and any other type of piece of iron that could contaminate the batch of raw material or a finished product. Another very important point is the protection of machinery and equipment, the grid prevents loose parts such as nails, screws, pieces of iron in general, from entering machines damaging them, causing greater damage.

Use

ATTENTION! CARE WITH MAGNETIC EQUIPMENT: We inform that people with any metallic prosthesis and/or pacemaker must keep their distance from magnetic equipment. Take due care when handling tools and/or metal parts near magnetic equipment, preventing possible accidents.